Control Systems Basics

Abstract

Published March 31, 2015

Controlling is a process that has five basic steps. This note describes these five basic steps in the control process. For brewery and brewpub managers already in operations, this may be the most strategic note that you read on this website, and it may also be the most important.

Why should I read this?

If you are in the food and beverage industry, control is the most important operational requirement to staying in business. Without proper controls in place your business will, over time, fail. This note gives you the basic architecture of the control process so that you can craft the controls that you need for your business to survive and thrive. We encourage you not just to read it and understand it, but to re-read it frequently, and implement the ideas within this paper often.

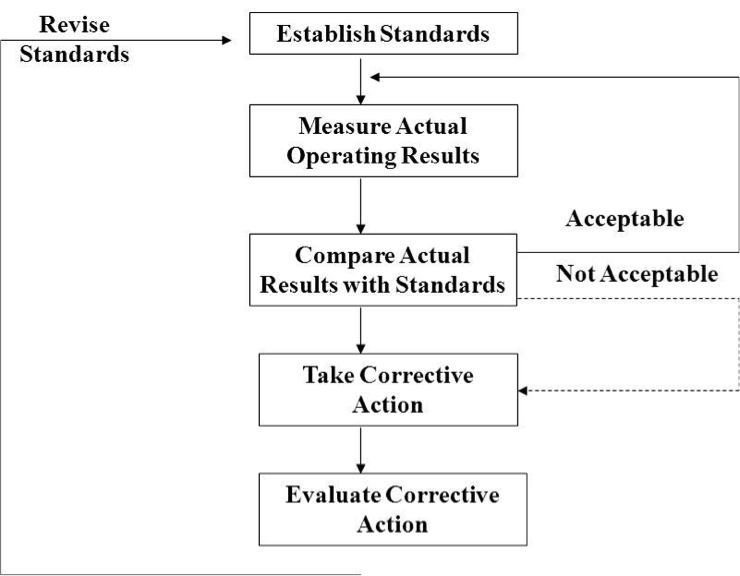

Figure 1: Standard Sequence For Implementing Standards and Controls (Source: Jack Ninemeier (2013). Planning and Control for Food and Beverage Operations. 8th Edition. American Home and Lodging Institute Publications. Page 39).

So many things in a brewery and a brewpub need to be controlled. The flavor of your beer, the cost of producing a sandwich, the amount of beer served in a pitcher, your revenue, sanitation, foodborne illness, customer satisfaction, food quality, speed of service, retail shelf space, illegal behavior, customer safety, alcohol abuse, employee theft…the list goes on and on. Figure 1 graphically demonstrates the control process. Please refer to this figure throughout your reading of this paper.

Standards

Leaders must set standards. In order to gain control over anything, the very first thing to do is to establish a standard. You will need standards for behavior, for processes, for outcomes, and for inputs, (see note on standards). Whenever you establish a standard, you must also establish how much variance from the standard is “ok” versus, “not ok.” For some standards, a lot of variance may be expected or allowed, while for other standards, you may have “zero tolerance.” Having standards is the first step in controlling operations to support your goals and your strategies.

Measure Actual Results

Once you have established a standard, you must measure actual results. Two summary points must be made here. First, the most important things to measure might not be easy to measure, yet they still must be measured. It is your job to figure out how to measure them well enough to check them against your standard. Sometimes it is only possible to measure actual results indirectly. In those cases, you are measuring “key indicators.” Indirect measurements are not ideal, but will have to do until you find a way to measure the results more directly.

Second, measuring actual results is not the same as measuring virtual results. While a computer or a point of sale device might list virtual sales, actual sales can only be determined by counting the revenue. Your inventory software may indicate that you should have five and a half barrels of winter ale left, but actual inventory can only be determined by the “look and see” method. (Click on the “look and see” link for a CAS forum thread that includes the production planning manager at Craft Brew Alliance) You may find that the amount of actual sales revenue is not the same as the virtual sales revenue on a printout, and you may find that there are only five barrels of ale left rather than five and a half.

Compare Actual Results to the Standard

Next, compare your actual results with your standard. If there is a big difference between the two, you will need to take corrective action. Corrective action is a manager’s job. Sometimes training is required, other times an interactive control like a meeting is what is needed, other times a policy or a rule, and other times what is needed is reinforcement of the values and belief systems of the organization. If actual results are always or nearly always in line with your standard, then management can put less and less emphasis on the control process around that standard. A periodic random sampling of measurements can be used on standards with little variation between actual results and standards. In these situations, instead of putting constant attention or measurement on those standards, shift your attention elsewhere to something more critical or with greater variance from those standards.

Evaluate Corrective Action

After corrective action is taken, management must determine if the corrective action is working. The actual results should be moving back toward the standard. After taking corrective action, it is important to focus on that standard until you are sure the new behaviors and processes are institutionalized into the culture of the operation. The standard should be measured regularly until management is satisfied with the results and relatively certain these standards will be upheld without their direct attention.

What should you be controlling?

Business owners should be controlling anything that is strategically critical, and should not be controlling, or minimally controlling anything that is not strategically important. For example, in almost all cases it is strategically important to set a “value proposition” standard and to put a carefully designed control system in place to make sure your business is actually delivering that value proposition to your customers. The balanced scorecard and the business model canvas are two frameworks that will help you make sure you have controls on the things that really matter. You can learn more about being strategic with your control systems in our white paper Strategic Control Systems.